Feeding Solutions by Afag/Aventics

Manufacturer: Afag-Aventics-Emerson

AVENTICS™ CAD/CAM feeding systems

Product Description

Optimize your production processes with AVENTICS CAD/CAM feeding systems. Engineered for precision and efficiency, these systems streamline material handling in manufacturing applications. With advanced CAD/CAM technology, AVENTICS feeding systems ensure seamless integration and operation, reduce downtime, and increase productivity. AVENTICS’ reliable and accurate CAD/CAM feeding solutions are the trusted choice for precise, efficient automated material handling and workflow efficiency in industrial settings.

Features

- Maximum system availability

- Complete reproducibility

- Cost benefits for repeat orders

- Highly precise production with 5-axis simultaneous processing and CAM use

- 10,000x proven primary polymer feeder bowl material

Product Description

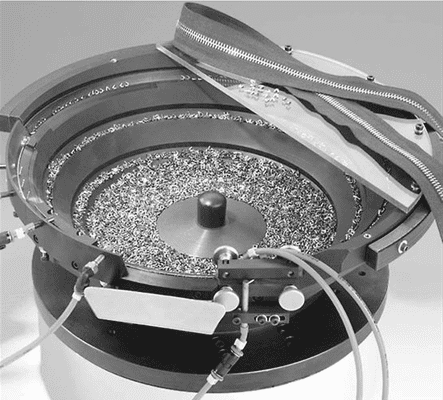

Engineered for clean room environments, AVENTICS material handling solutions offer exceptional performance and hygiene compliance. With advanced technology and a robust design, our feeding products excel in handling delicate components with precision and deliver optimal productivity in demanding clean room settings. For precise, reliable operation an increased efficiency in environments with the highest hygienic standards, trust in clean room feeding solutions from AVENTICS.

Features

- Verified clean room suitability according to ISO Class 7

- Design standards for medical technology applications guarantee easy cleaning

- Multiple parts supply with preferably electric Afag Handling

- Vibrating conveyor pots made from FDA polyamide, aluminium or stainless steel

- Use of medical approved materials with material certificate

- Sorting pots made from high-alloyed and polished stainless steel sheets

AVENTICS™ Clean room feeding

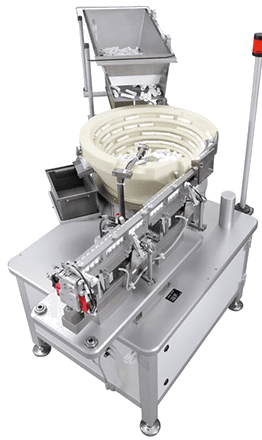

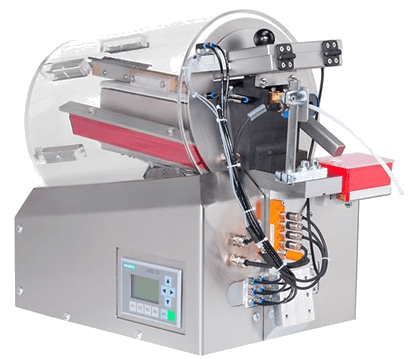

AVENTICS™ Series Smart FEG Spring feeder device

Product Description

The AVENTICS Spring feeder device/Smart FEG is designed to deliver efficient, precise, and reliable performance in your material handling systems. Engineered with advanced technology, these feeders offer precise and seamless feeding of components or parts. With a robust design and smart functionality, AVENTICS Smart FEG enables optimized production processes, smooth operation, and increased productivity in your material handling and feeding systems in industrial settings.

Features

- Our proven spring feeder device (FEG) got an upgrade: The Smart FEG now comes with an integrated compact control system that, just like our drum conveyor, can access all functions and settings via an intuitive menu on the integrated touchpad. Optionally, ring sensors for detecting the filling levels of the tubes can be managed straight from the small control system.

Product Description

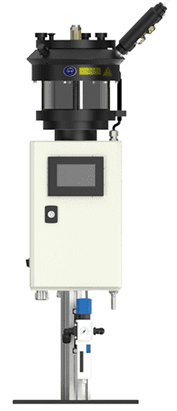

AVENTICS versatile Drum Feeder products are designed for efficient material handling in industrial automation setups. Engineered with advanced technology, these feeders offer reliable and precise feeding of components or parts. With a robust design and high-speed capabilities, AVENTICS Drum Feeders excel in optimizing production processes, ensure seamless operation and increase productivity. Easy-to-use AVENTICS drum feeders drive efficiency in material handling and feeding solutions while enhancing overall automation performance.

Features

- Many available untangling systems allow the ideal adaptation to your individual application

- Reliable untangling and sorting of coils and other conveyed items

- Innovative solutions for difficult part geometries

- High reliability due to automated dejamming mechanisms

- Electric coil sorting with linear motor technology that can be deployed self-sufficiently

AVENTICS™ Drum Feeder

AVENTICS™ Spring Feeding

Product Description

AVENTICS Spring feeding solutions are engineered to deliver precise, reliable production by ensuring the safe, accurate feeding of springs in industrial applications. With advanced technology and user-friendly interfaces, they enhance automation performance, help reduce downtime and improve productivity. Trust in AVENTICS for innovative and dependable spring feeding solutions that streamline material handling, ensuring smooth and efficient manufacturing operations.

Features

- Many available untangling systems allow the ideal adaptation to your individual application

- Reliable untangling and sorting of coils and other conveyed items

- Innovative solutions for difficult part geometries

- High reliability due to automated dejamming mechanisms

- Electric coil sorting with linear motor technology that can be deployed self-sufficiently

Literature