UNIMOTION is a leading company in the industrial automation field, at a global level. Combining innovative engineering solutions - Unimotion helps companies of all sizes across a wide range of industrial segments. Unimotion develops Industry 4.0-enabled products and systems with leading quality, performance and value. Engineering, Production, Construction, Warehouse, Research & Development department; all this can be found under one roof. Thanks to years of experience and a consistent focus on automation technology, Unimotion is continually improving their products and implementing new innovations that provide customers with many technical advantages.

Linear units

Drive types: Ball screw, Belt, Linear motor

Repeatability: Up to ± 0,001 mm

Travel speed: Up to 10 m/s

Max. Stroke: Up to 5970 mm

Max. Axial Load: Up to 29600 N

Unimotion's compact linear units with toothed belt drive or ball screw drive provide high-performance features such as High speeds, great accuracy, and repeatability. Integrated with zero clearance guide rail system and in one step machined internal surfaces for precise and optimal movements.

Linear motors

Series: LMCA, LMLA

Continuous force: Up to 1856 N

Peak force: Up to 4215 N

Max. Supply Voltage: 600 V DC

Max. winding temperature: 125°C

Low cogging force

Cables suitable for the cable chains

Low installation height

The linear motor-driven systems in comparison with the traditional linear units, are more compact, accurate, repeatable, faster, robust, reliable, generate less noise and after all, require no maintenance. Linear motors are also known as “direct-drive” motors because the load is directly coupled onto them.

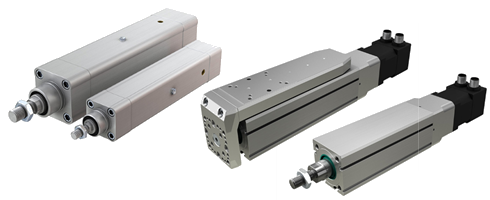

Electric cylinders

Types: PNCE, MCE, MSCE

Travel speed: Up to 2,5 m/s

Max. Stroke: Up to 1500 mm

Max. Axial Load: Up to 29000 N

Unimotion's electric cylinder with a built-in precision ball screw drives with reduced Backlash and a non-rotational piston rod. High-performance features such as high speeds, good positioning, accuracy, and high repeatability. The electric cylinders can be

additionally equipped with switches and accessories that cover a wide range of applications.

Stepper systems

Plug & Drive

Motor sizes: 28, 42, 56

Communications: Profinet, Ethernet, EtherCAT, Pulse/direction

Closed-loop system

No gain tunning

Brake control

Closed-loop UNIMOTION stepper systems consists of a stepper motors and

drives which offer a simple Plug & Drive solution for precise automation, with Profinet, Ethernet, EtherCAT and Pulse-direction communication so that each application can be personalised according to individual specifications.

Literature