AC Series Compact Axes by Zimmer

Manufacturer: Zimmer

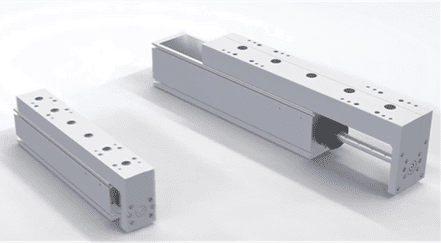

Compact axes are a key element in modern automation technology. The space-saving design of the AC series enables high production flexibility and efficiency in a wide range of applications. It combines precise linear motion with powerful, integrated drives – in the smallest of spaces. This means that they can be easily integrated into existing systems and combined with each other to increase the efficiency and performance of your automated processes. Thanks to high speed and fast acceleration, you don’t have to compromise on performance even when space is limited.

Discover the benefits of the AC series and find out how you can take your production efficiency to a new level!

- High precision and load capacity

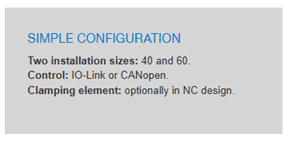

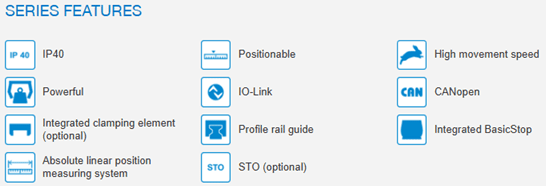

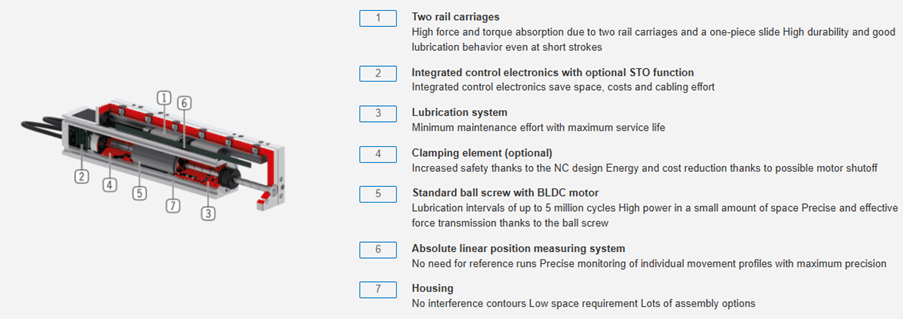

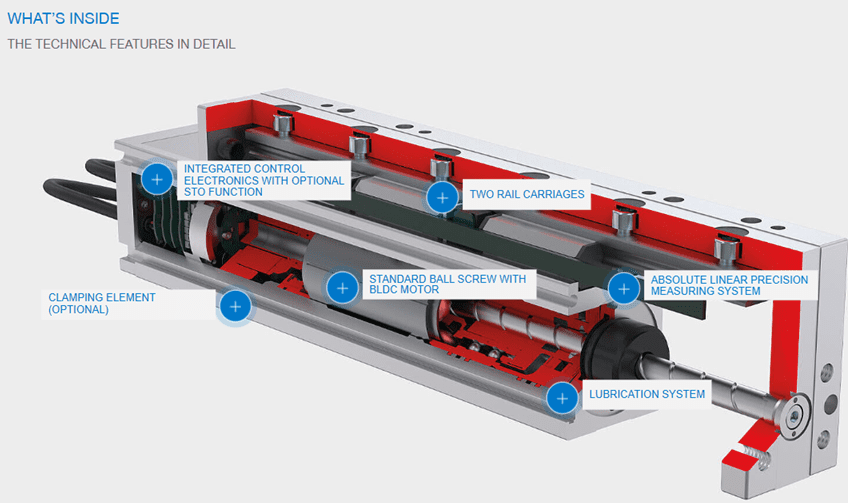

The BLDC motor, combined with the ball screw, ensures precise and dynamic movements. The one-piece slide, milled from a solid block, reliably absorbs the loads together with the double rail carriages over millions of cycles. - Integrated control electronics with optional STO function

The integrated control electronics (optionally IO-Link or CANopen control) with optional safe torque off function provide additional security. This means that the application can be brought into operation more quickly, since there is no complicated cabling or configuration work needed. - Low space requirement and efficient in operation

Despite its compact external dimensions, an optional clamping element can be integrated that holds the slide securely and energy-efficiently in any position of its freely configurable movement profile.

MAXIMUM PERFORMANCE IN MINIMAL SPACE

TAKE ADVANTAGE OF THE BENEFITS OF THE AC SERIES

IO-Link for uncomplicated commissioning and implementation of simple applications or CANopen for real-time interaction with other machine elements.

Ball screw drive with BLDC motor:

For fast and powerful movements with high precision.

Optionally with safe torque-off function:

Maximum safety thanks to fast and safe torque switch-off.

High load capacity and durability:

Thanks to linear guide with double rail carriages and one-piece carriage milled from solid material.

Individual motion profiles:

Freely configurable parameters allow a movement perfectly adapted to your application.

Compact design with no interference contours and an unbeatable ratio of size to stroke.

Absolute precision:

High positioning and repeat accuracy without reference runs thanks to integrated, absolute position measuring system.

Minimal maintenance requirement:

Lubrication intervals of up to 5 million cycles with a service life of up to 100 million cycles.

Low operating costs:

Motor shutdown at standstill also possible for vertical applications thanks to combination with clamping element.

THE COMPACT AXES IN USE

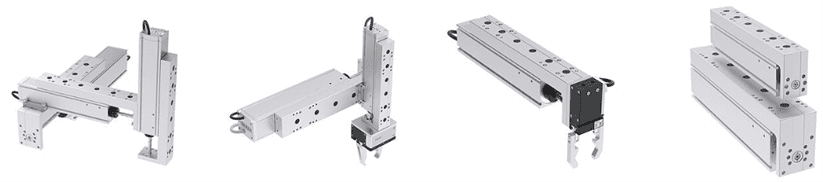

COMBINATIONS FOR EVERY APPLICATION

FAST, PRECISE, REPEAT ACCURACY

Our compact axes are an integral part of automated processes in many industries. They are ideal for applications where fast, precise and repeatable movements are required – millions of times over. The following examples give you a detailed insight into specific applications for compact axes and show how you can increase the efficiency and precision of your automation processes.

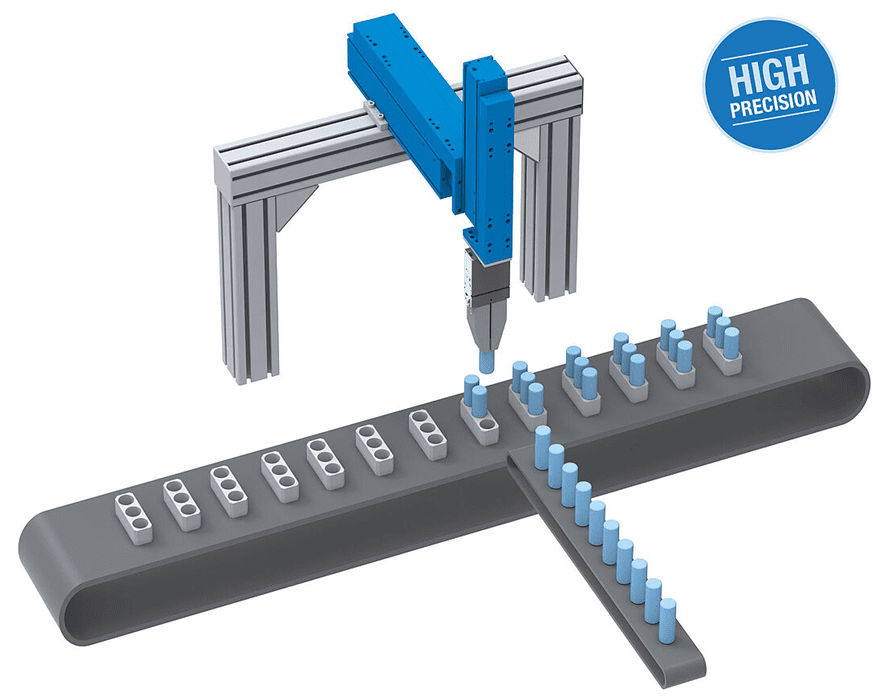

PICK & PLACE

In this application, our compact axes score points with high cycle rates and speeds when placing products, as required in the packaging industry, for example. This ensures a high product throughput and a significant increase in production output.

OUR EXPERTISE – YOUR ADVANTAGES

- End effector variety: Compatible with the entire Zimmer Group range of grippers

- Compact size: Unprecedented stroke and design length ratio

- Dynamic: Maximum speed and acceleration

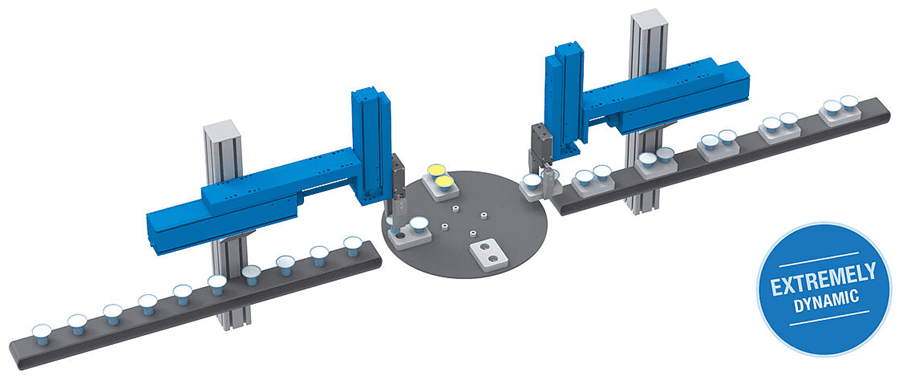

INTELLIGENT AXES COOPERATION

Precise synchronous-cyclical motion sequences are essential for processes with multiple axes, such as here when handling and testing LEDs on the rotary indexing table. Even in confined spaces, the compact design of the AC series enables precise execution. The precision of the compact axes enables high product quality and process reliability to be achieved.

OUR EXPERTISE – YOUR ADVANTAGES

- Synchronous cyclic movements using CANopen

- A rigid design enables high accelerations and speeds for high cycle rates

- Actuator and axis form a single unit with a minimal interference contour

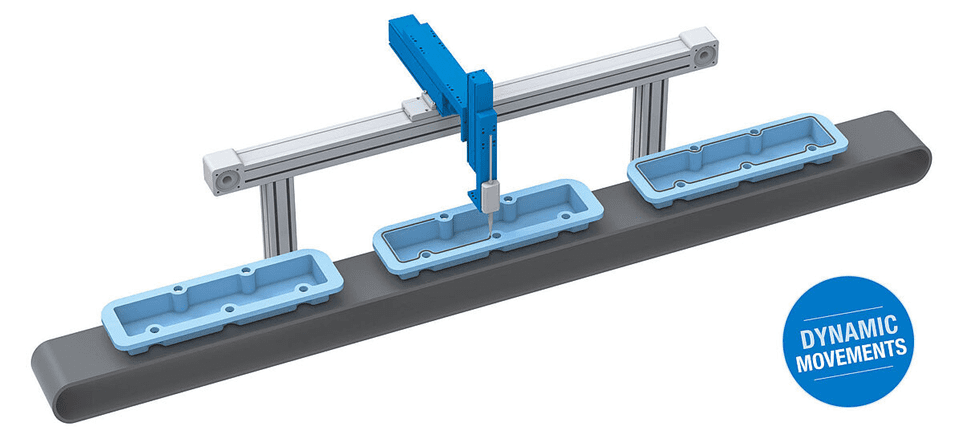

SYNCHRONOUS CYCLIC MOVEMENTS

Numerous applications require not only simple linear movements, but also complex movement profiles by combining several axes. Compact axes were combined with a dispenser to apply liquid sealant to covers. The use of CANopen technology makes it possible to apply exactly the right amount of sealant in the right place, even for complex structures.

OUR EXPERTISE – YOUR ADVANTAGES

- Flexible combination of axes with one another due to a clever design

- Optimal cost-benefit ratio

- Easy commissioning with minimal maintenance

Watch Video

Literature