Hydraulic Feed Contollers by ACE Controls

Hydraulic Feed Controls

Regulate feed rates in the best way

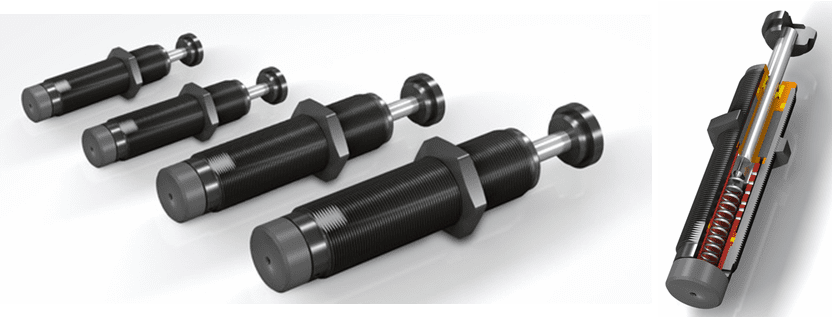

These maintenance-free, ready-to-install hydraulic feed controls are self-contained hydraulic elements regulated by a precision throttle. The feed rate is set from the outside by turning the setting adjuster. The tried-and-tested rolling diaphragms used in many ACE shock absorbers also serve as a dynamic sealing element for a hermetic seal as well as volume compensation for the piston rod and provide the resetting of the piston when the force is removed.

Hydraulic Feed Controls

MA, MVC

Designed for applications with low precision requirements

Adjustable

Compression force 2 lbs to 800 lbs

Stroke 0.28 in to 1.58 in

Many application options: the hydraulic feed controls in models MA and MVC are similar to that of the VC model. However, these hydraulic controls have been designed for applications that require less precision.

There are also plenty of accessories for the MA and MVC models. All products are ready-to-install, maintenance-free, stable in temperature and avoid stick-slip effect. Speeds from 0.47““/min. (12 mm/min.) can be driven at a low thrust force using the adjustment screw on the base of the hydraulic control.

Hydraulic feed controls with the designations MA and MVC are especially used in handling modules or linear carriages and also for applications with changing usage data.

Technical Data

| Compression force 2 lbs to 800 lbs

Stroke 0.28 in to 1.58 in Execution Thread M8 to M25 Impact velocity range At speeds of 0.98 ft/sec the maximum allowed energy is approx. 17.70 in-lbs. Where higher energies occur use a shock absorber for the initial impact. Avoid high impact velocities. Adjustment Hard impact at the start of stroke, adjust the ring towards 9 or PLUS. Hard impact at the end of stroke, adjust the ring towards 0 or MINUS. Positive stop Integrated Damping medium Oil, temperature stable Material Outer body: Nitride hardened steel; Piston rod: Steel with black oxide finish or nitride hardened Mounting In any position Operating temperature range 32 °F to 150 °F Application field Handling modules, Linear slides, Automatic machinery, Conveyor equipment, Absorption control |

Hydraulic Feed Controls

VC25

For precision adjustment of feed rates

Adjustable

Compression force 6.74 lbs to 787 lbs

Stroke 0.59 in to 4.92 in

As the hydraulic oil is forced out through the throttle opening, a constant feed rate is achieved on the stroke. In the models up to 2.17““ (55 mm) stroke, the tried and tested rolling diaphragm, known from ACE shock absorbers, serves as a dynamic seal, as volume compensation of the piston rod and as a reset element.

Precision hydraulic feed controls of the product family VC are used in automotive and industrial applications as well as in mechanical engineering and the electronics industry.

Technical Data

| Compression force 6.74 lbs to 787 lbs

Stroke 0.59 in to 4.92 in Execution F = Ø 0.94 in without thread Piston rod diameter Ø 0.31 in Impact velocity range At speeds of 0.98 ft/sec the maximum allowed energy is approx. 8.85 in-lbs for units up to 2.16 in stroke and approx. 17.70 in-lbs for units 2.95 in to 4.92 in stroke. Where higher energies occur use a shock absorber for the initial impact. Avoid high impact velocities. Adjustment Infinitely adjustable Positive stop External positive stops 0.04 in to 0.06 in before the end of stroke provided by the customer. Damping medium Oil, temperature stable Material Outer body: Black anodized aluminium; Piston rod: Hard chrome plated steel; Accessories: Steel with black oxide finish or nitride hardened Mounting In any position Operating temperature range 32 °F to 140 °F Application field Handling modules, Linear slides, Automatic machinery, Conveyor equipment, Absorption control |