Heavy Industrial Shock Absorbers by ACE Controls

Manufacturer: ACE Controls

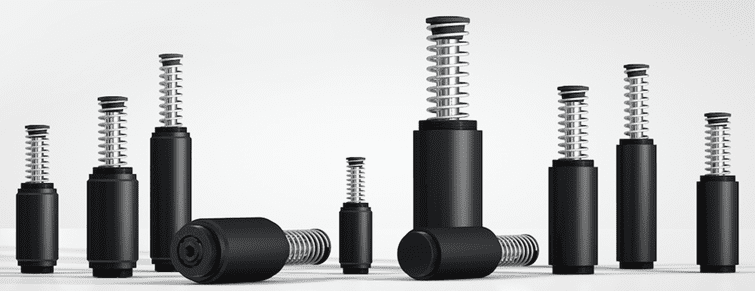

Heavy Industrial Shock Absorbers

Effective shock absorption for heavy loads

Whichever design is chosen, this type of shock absorber impresses with its robustness and operational readiness wherever heavy loads need to be reliably stopped on-the-spot and at a precise point.

The CA4 models can absorb up to 1,120,000 in/lbf (126,500 Nm) of energy. The series of heavy duty, self-compensating “CA“ types are equally suitable for use as an emergency stop as are the adjustable types with the designations “A“. The range of effective loads covered is increased considerably for this purpose.

Heavy Industrial Shock Absorbers

A1 1/2 to A3

Deceleration of heavy loads and progressive adjustment

Adjustable

Energy capacity 21,000 in-lbs/Cycle to 390,000 in-lbs/Cycle

Stroke 2.00 in to 12.00 in

Their special aspect is the flexibility, as all the absorbers can be adjusted using a socket on the absorber base and be perfectly adapted to the application. The A models cover a range of effective weights from 0.66 lbs to 449,743 lbs. (0.3 to 204,000 kg) and can absorb up to 389,433 in-lbs. (44,000 Nm) energy.

These heavy duty, adjustable ACE industrial shock absorbers are the first choice in heavy duty applications and generally in heavy industrial maching design when the usage data has not been exactly determined.

Technical Data

| Energy capacity 21,000 in-lbs/Cycle to 390,000 in-lbs/Cycle

Stroke 2.00 in to 12.00 in Impact velocity range 0.5 ft/sec to 15 ft/sec. Other speeds on request. Operating temperature range 10 °F to 150 °F. Other temperatures on request. Mounting In any position Positive stop External positive stops 0.10““ to 0.12““ before the end of stroke provided by the customer. Adjustment Hard impact at the start of stroke, adjust the ring towards 9. Hard impact at the end of stroke, adjust the ring towards 0. Material Outer body: Steel corrosion-resistant coating; Piston rod: Hard chrome plated steel; Rod end button: Hardened steel and corrosion-resistant coating; Return spring: Zinc plated steel Damping medium Automatic Transmission Fluid (ATF) Application field Portal systems, Machines and plants, Conveyor systems, Crane systems, Loading and lifting equipment, Impact panels, Heavy load applications, Swivel units, Shelf storage systems |

Heavy Industrial Shock Absorbers

CA2 to CA4

Deceleration of heavy loads

Self-Compensating

Energy capacity 21,000 in-lbs/Cycle to 1,120,000 in-lbs/Cycle

Stroke 2 in to 16 in

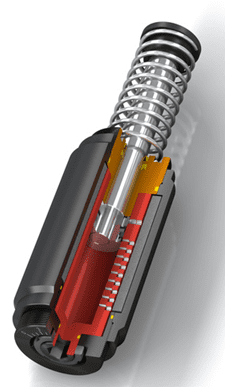

Powerful: The weight of these high capacity absorbers are between 28.2 lbs and 322 lbs. (12.8 and 146 kg). They complement ACE's product range of self-compensating shock absorbers. All models from this product family are designed for applications where robustness and large energy absorption are important.

ACE uses our proprietary custom calculation program to design each shock absorber for the specific customer application. Customization helps reduce the risk of crashes and incorrect product sizing. The CA models can absorb up to 1,119,620 in-lbs (126,500 Nm) of energy and can be used in the area of effective weights between 1,543 lbs and 718,707 lbs. (700 kg and 326,000 kg). The combination of being extremely solid, absorbing high levels of energy and having a large damping range makes them invaluable. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These heavy duty self-compensating industrial shock absorbers are primarily used in heavy industrial engineering e.g. on lift bridges and steel structures or for damping sluice systems.

Technical Data

| Energy capacity 21,000 in-lbs/Cycle to 1,120,000 in-lbs/Cycle

Stroke 2 in to 16 in Impact velocity range 1 ft/sec to 16.5 ft/sec. Other speeds on request. Operating temperature range 10 °F to 150 °F. Other temperatures on request. Mounting In any position Positive stop External positive stops 0.10““ to 0.12““ before the end of stroke provided by the customer. Material Outer body: Steel corrosion-resistant coating; Piston rod: Hard chrome plated steel; Rod end button: Hardened steel and corrosion-resistant coating; Return spring: Zinc plated steel Damping medium Automatic Transmission Fluid (ATF) Application field Portal systems, Machines and plants, Conveyor systems, Crane systems, Loading and lifting equipment, Shelf storage systems, Heavy load applications, Swivel units |