Industrial Gas Springs by ACE Controls

Manufacturer: ACE Controls

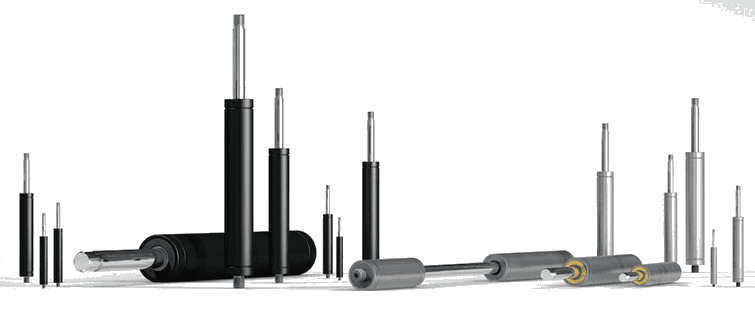

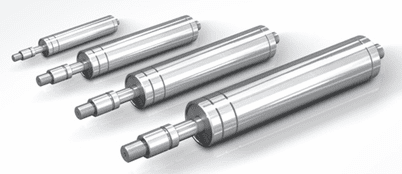

Industrial Gas Springs – Push Type

The smart way to lift and lower

Available with body diameters of 0.31“ to 2.76“ (8 to 70 mm) and forces from 2 to 2,925 lbs. (10 to 13,000 N), ACE push type gas springs offer a huge variety and maximum service life. The first is achieved thanks to the number of available connections and fittings for simple attachment and the latter with high quality design and materials. Whether they are made of steel or stainless steel, these components make any work easier and are also visually appealing.

Industrial Gas Springs – Pull Type

Alternatives for tight spaces and mounting requirements

If ACE gas push type springs cannot be used due to a lack of space, ACE's industrial gas pull type springs come into their own. These compact assistants with body diameters of 0.59“ to 1.57“ (15 to 40 mm) are effective in the direction of traction and work in the opposite way to the principle of gas push type springs.

This means that the gas pressure in the cylinder draws the piston rod in and, when closing a flap for example, supports the manual force required for a controlled motion. ACE's gas pull type springs are also self-contained, maintenance-free machine elements and equipped with a standard valve to individually regulate the gas pressure, whereby they cover forces between 7 to 1125 lb (30 and 5,000 N). The ability to mount in any orientation and position along with an extensive range of DIN standardized accessories enable universal use.

Industrial Gas Springs – Push Type

GS-8 to GS-70

Individual stroke length and extension forces

Valve Technology

Extension force 2 lbs to 2,923 lbs

Stroke 0.79 in to 39.37 in

They are filled according to individual customer pressure requirements and may be adjusted later by use of a built-in valve. ACE provides free calculation support and designs the gas springs with mounting points specifically for the particular application. A variety of accessories makes assembly even easier and allows universal application of the gas springs.

ACE industrial gas push type springs are used on covers, lids, or other components. They are used in industrial applications, automation and machine building, medical technology as well as in the electronics, automobile and furniture industries.

Technical Data

| Extension force 2 lbs to 2,923 lbs

Stroke 0.79 in to 39.37 in Piston rod diameter Ø 0.12 in to Ø 1.18 in Progression Approx. 13 % to 76 % (depending on size and stroke) Lifetime Approx. 32,808 ft Operating temperature range -4 °F to 176 °F Material Outer body: Coated steel; Piston rod: Steel or stainless steel with wear-resistant coating; End fittings: Zinc plated steel Operating fluid Nitrogen gas and oil Mounting We recommend mounting with piston rod downwards to take advantage of the built-in end position damping. End position damping length Approx. 20 % to 67 % (depending on size and stroke) Positive stop External positive stop at the end of stroke provided by the customer. Application field Hoods, Shutters, Machine housing, Conveyor systems, Control boxes, Furniture industry, Jacking applications, Assembly stations, Vehicle technology, Folding elements |

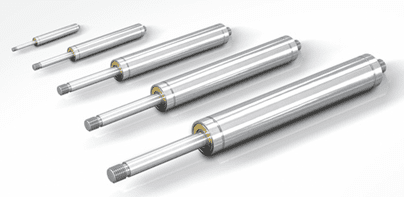

Industrial Gas Springs – Push Type

GS-8-V4A to GS-40-VA

With food grade oil for FDA compliance

Valve Technology, Stainless Steel

Extension force 2 lbs to 1,124 lbs

Stroke 0.79 in to 27.56 in

These ACE gas springs not only look good, they are also available in various stroke lengths and extension forces. A comprehensive range of accessories in stainless steel guarantees easy assembly and a broad range of uses.

ACE stainless steel industrial gas springs are used in the automotive sector, in industrial applications, automation and machine building and medical clean room technology as well as in the food, electronics and shipbuilding industries.

Technical Data

| Extension force 2 lbs to 1,124 lbs

Stroke 0.79 in to 27.56 in Piston rod diameter Ø 0.12 in to Ø 1.18 in Progression Approx. 13 % to 59 % (depending on size and stroke) Lifetime Approx. 32,808 ft Operating temperature range -4 °F to +176 °F Material Outer body, Piston rod, End fittings: Stainless steel (1.4301/1.4305, AISI 304/303 and 1.4404/1.4571, AISI 316L/316Ti) Operating fluid Nitrogen gas and HLP oil according to DIN 51524, part 2 Mounting We recommend mounting with piston rod downwards to take advantage of the built-in end position damping. End position damping length Approx. 0.2 in to 1.18 in (depending on the stroke) Positive stop External positive stop at the end of stroke provided by the customer. Application field Hoods, Shutters, Machine housing, Conveyor systems, Control boxes, Furniture industry, Shipbuilding, Food industry, Pharmaceutical industry, Folding elements |

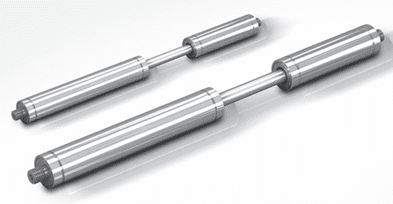

Industrial Gas Springs – Push Type

GST-40 Tandem

Optimized dual force for heavy flaps and wide angle applications

Valve Technology

Extension force 67 lbs to 1,124 lbs

Stroke 1.97 in to 15.75 in

A comprehensive range of accessories guarantees easy assembly and a broad range of uses, are specifically suitable for heavy loads with large opening angle. Stainless steel versions are available to meet environmental or appearance requirements.

Tandem push type gas springs from ACE are used in industrial applications such as in automation and machine building, in the automobile, electronics and furniture industries, but also in medical technology as well as for service hatches.

Technical Data

| Extension force 67 lbs to 1,124 lbs

Stroke 1.97 in to 15.75 in Piston rod diameter Ø 0.79 in Progression According to calculation relating to your application. Lifetime Approx. 32,808 ft Operating temperature range -4 °F to +176 °F Material Outer body, End fittings: Zinc plated steel; Piston rod: Steel with wear-resistant coating Operating fluid Nitrogen gas and oil Mounting In any position. Please adopt the mounting points determined by ACE. End position damping length Application-specific end position damping and extension speed. Positive stop External positive stop at the end of stroke provided by the customer. Application field Hoods, Shutters, Machine housing, Conveyor systems, Folding elements, Loading and lifting equipment |

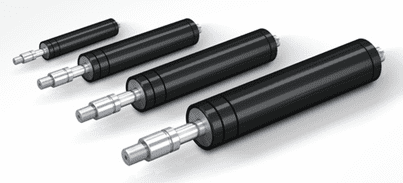

Industrial Gas Springs – Pull Type

GZ-15 to GZ-40

Very low progression rate

Valve Technology

Traction force 9 lbs to 1,124 lbs

Stroke 0.79 in to 25.59 in

ACE pull type gas springs offer the maximum service life thanks to the solid chrome-plated piston rod and an integrated sliding bearing. The maintenance-free and ready-to-install products are available in body diameters of 0.59““ to 1.57““ (15 to 40 mm) as well as forces from 8.99 lbs to 1,124 lbs. (40 to 5,000 N) and are available from stock with valve and a large selection of accessories. The traction force can be fine-tuned using the adjustment valve.

Gas traction springs from ACE are used in industrial applications, automation and machine building, especially in test equipment and in medical technology as well as in the electronics and furniture industries.

Technical Data

| Traction force 9 lbs to 1,124 lbs

Stroke 0.79 in to 25.59 in Piston rod diameter Ø 0.16 in to Ø 1.10 in Progression Approx. 12 % to 45 % Lifetime Approx. 6,561 ft Operating temperature range -4 °F to +176 °F Material Outer body, End fittings: Zinc plated steel; Piston rod: Steel or stainless steel with wear-resistant coating Operating fluid Nitrogen gas Mounting With piston rod upwards. End position damping length Without damping. For end position damping use damping material (e.g. TUBUS or SLAB). Positive stop External positive stop at the end of stroke provided by the customer. Application field Hoods, Shutters, Machine housing, Conveyor systems, Control boxes, Furniture industry, Shipbuilding, Assembly stations, Vehicle technology, Folding elements |

Industrial Gas Springs – Pull Type

GZ-15-V4A to GZ-40-VA

Very low progression rate with FDA approval

Valve Technology, Stainless Steel

Traction force 9 lbs to 1,124 lbs

Stroke 0.79 in to 23.62 in

This high quality design is rust free and is more robust against environmental impact compared with standard gas pull type springs. These stainless steel gas springs are also visually appealing, very durable and available, upon request, in many stroke lengths and traction forces. A comprehensive range of accessories in stainless steel guarantees easy assembly and a broad range of uses.

ACE industrial push type springs made of stainless steel are used in industries such as the chemical and food industry, in automobiles, plant engineering and shipbuilding and also in medical, military, environmental and water supply technology.

Technical Data

| Traction force 9 lbs to 1,124 lbs

Stroke 0.79 in to 23.62 in Piston rod diameter Ø 0.16 in to Ø 1.10 in Progression Approx. 11 % to 45 % Lifetime Approx. 50,000 cycles Operating temperature range -4 °F to +176 °F Material Outer body, Piston rod, End fittings: Stainless steel (1.4301/1.4305, AISI 304/303 and 1.4404/1.4571, AISI 316L/316Ti) Operating fluid Nitrogen gas Mounting With piston rod upwards. End position damping length Without damping. For end position damping use damping material (e.g. TUBUS or SLAB). Positive stop External positive stop in the pulling direction provided by the customer. Application field Hoods, Shutters, Machine housing, Conveyor systems, Control boxes, Furniture industry, Shipbuilding, Food industry, Pharmaceutical industry, Folding elements |