IO-Link Wireless by Zimmer Group

Manufacturer: Zimmer

YOUR BENEFITS

- Compatible with all Zimmer Group IO-Link gripper components, no matter which robot or system base

- No complicated wiring through the robot or the system needed

- No mechanical obstacles or broken wires, thanks to wireless communication

- Scalable, easy expansion with additional grippers due to pairing at the master

Wireless functionality for all IO-Link grippers

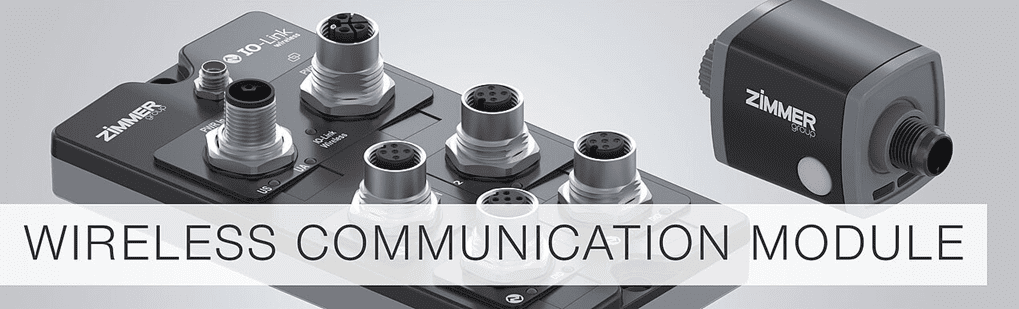

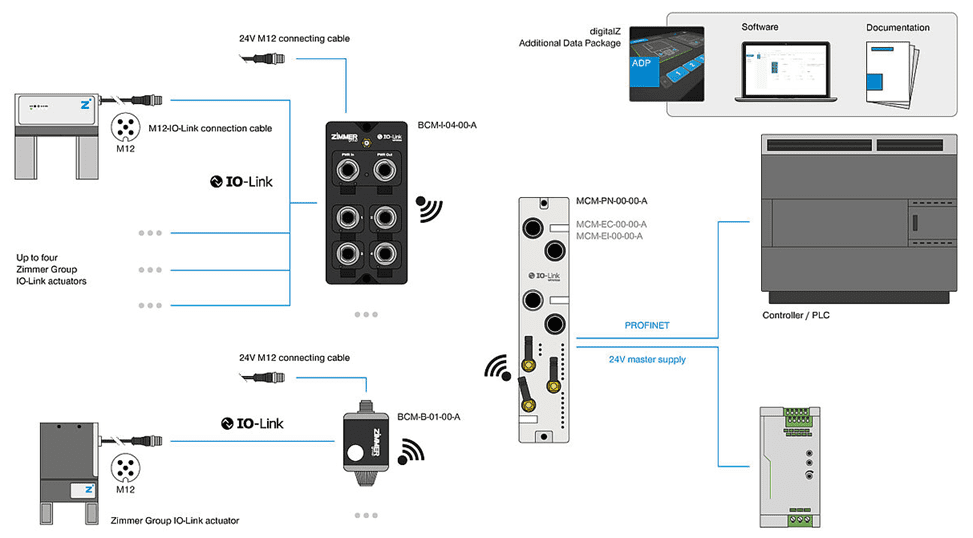

BRIDGE COMMUNICATION MODULE

Especially in robotics, the last robot axis, also called the wrist, lacks an appropriate electrical interface for intelligent grippers because this connection is often not available with a suitable cable in the robot arm. This problem is usually solved by routing an external cable along the robot arm. However, this results in some disadvantages, like in the robot's freedom of movement. Wireless transmission of the required signals and information provides a solution. The combination of BCM [Bridge Communication Module] and MCM [Master Communication Module] offers precisely this functionality. The only thing needed at the actuator is the power supply – an effective solution, not just for robotics.

Interference-free communication

With the new IO-Link bridge communication modules, the connecting lines between the gripper and the control system can be significantly reduced, while maintaining the same performance and functionality as wired solutions. The features mentioned above allow the new bridge modules to communicate with a wireless IO-Link master securely and without interference. This enables real-time latency times of 5 ms for communication with up to 40 devices for maximum reliability and flexibility in production. The reliability is above a packet error rate (PER) of 10-9.

Two variants BCM-B and BCM-I available

Two versions of the bridge module are currently available. One is the BCM-B, a model that can be positioned decentrally in the wiring harness and enables the connection of an IO-Link actuator. The other is the BCM-I, which allows the use of up to four IO-Link devices. For example, this means that several Zimmer Group grippers and IO-Link-capable sensors can be used at the same time.

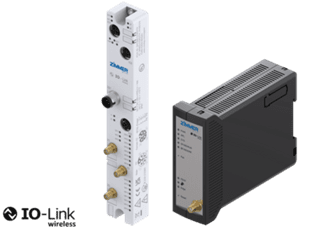

BCM SERIES

Powerful and flexible

The BCM series modules have a current carrying capacity of 4 or 5 amperes. As a result, there are no compromises when it comes to selecting the end effectors and the modules can even control high-performance grippers.

- All Zimmer Group IO-Link components can be used, regardless of the structure of the existing robot / system base

- No complex cable routing through the robot or system (slip rings, contact elements etc. not required)

- No source of error due to moving data cable (mechanical obstacle, broken wire) wearing part eliminated

- Wireless range of point-to-point communication up to 10 m, up to 30 m with unobstructed view

- Scalable, simple expansion of further grippers by logging on to the master

- Industrial design

- IP67 certified

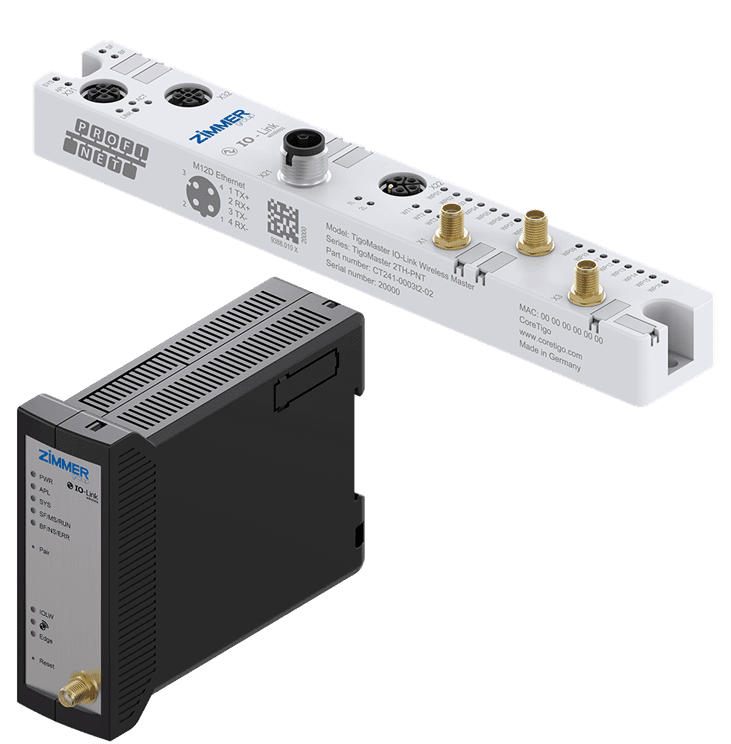

MCM series

Reliable data transmission

The counterpart to the BCM. With the Master Communication Module, you receive secure, reliable transmission of data through redundant signals and a maximum packet data error rate of 10⁻⁹.

- All Zimmer Group IO-Link components can be used, regardless of the structure of the existing robot / system base

- No complex cable routing through the robot or system (slip rings, contact elements etc. not required)

- No source of error due to moving data cable (mechanical obstacle, broken wire) wearing part eliminated

- Wireless range of point-to-point communication up to 10 m, up to 30 m with unobstructed view

- 8 advanced grippers, 16 basic grippers or 16 digital devices

- Industrial design

- IP67 certified

- Secure and reliable communication thanks to redundant signals and a maximum packet data error rate of 10-⁹

ZIMMER GROUP END EFFECTORS – INTEGRATION WITH IO-LINK WIRELESS TECHNOLOGY

The grippers connected to the bridge modules are controlled by an MCM, which can be integrated into its different variants at fieldbus level. In addition to the specific functional modules for controlling our I/O link grippers, the corresponding instructions are also available. Everything from a single source – so you reach your goals quickly.

Literature