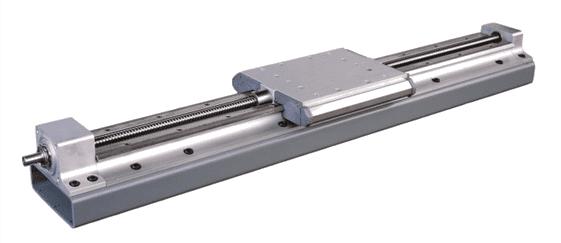

Lo Pro Linear Actuator by Bishop Wisecarver

LoPro linear actuators are an actuated linear motion system based upon proven DualVee guide wheel technology for smooth and quiet motion over long lengths. Actuation options include AT series belt, ANSI roller chain, lead screw, and ball screw. LoPro linear actuators are also available in a non-actuated version. LoPro linear actuators provide a tough, cost effective, low friction, low profile modular solution, built to withstand a wide range of operating environments. Complete systems include your preference of wiper or basic wheel plates, and may be mounted or un-mounted. Support beams are available in aluminum or steel to meet application demands and to provide ease of installation. A wide variety of gantry brackets are available to form complete LoPro gantry systems.

Undriven Assemblies

In the most basic form, LoPro is available as a rigid and compact linear guide rail. Although it is designed as an actuator with drive mechanisms, LoPro sub-assemblies can be used as standalone linear guides. The linear bearing track plate assemblies can be constructed in very long lengths with carbon steel or stainless steel 90-degree vee guide track. Wheel plate assemblies with mating 90-degree guide wheel bearings can be used on the linear track plate guideways to create heavy load capacity linear bearings. The track plate bases are made from precision machined extruded aluminum and provide an accurate platform.

Belt-Driven Actuators

Belt-driven LoPro actuators are ideal for long travel lengths and high speeds. Belt drives feature AT-style reinforced polyurethane belting. Belt drive systems may be mounted to either steel or aluminum support beams and come with your choice of the wiper wheel plate or the basic wheel plate. Corrosion-resistant versions are available, as are multiple wheel plates.

Chain-Driven Actuators

Chain-driven LoPro actuators are available with standard or corrosion resistant ANSI roller chains. The chain driven LoPro is ideal for vertical hoisting and large load actuation over long travel lengths. Aluminum and steel support beams may be used to mount the chain drive. Other options include basic and wiper wheel plates, with or without multiple wheel plates.

Lead Screw Actuators

Lead screw -driven LoPro actuators feature either BY or NTBY lead screw nut types to meet your backlash requirements. Metric and inch screw leads are also available in lead accuracies to 0.0006 in/in (mm/mm). Lead screw actuators may be selected with steel or aluminum support beams and with your preference of basic or wiper wheel plates.

Ball Screw Actuators

Metric ball screw -driven actuators are accurate to 0.004 in/ft (0.1 mm /300mm). Ball screws are available in standard and corrosion-resistant materials to meet environmental constraints. Basic or wiper wheel plates may be selected, as well as steel or aluminum support beams.

Actuator Configuration Options

There are many possible design configurations of LoPro actuators and each actuator is made to specification from standard sub-assemblies and components. The system travel, or stroke length, must always be defined. The standard versions include your choice of carbon steel or stainless steel hardware and linear bearing elements. The belt- and chain-driven versions have several options for the drive shaft output side and include left hand output, right hand output, and dual shaft output. The dual shaft version is ideal for coupling a rigid shaft between two parallel actuators and driving the system with one motor. Please inquire with a BW application engineering for additional accessories such as travel limit sensors and sensor flags, optional tools, individual replacement parts, and other support products.