Match by Zimmer Group

Manufacturer: Zimmer

End-of-Arm Ecosystem

Discover MATCH! The standardized interface combines the two main handling technologies: gripping and vacuum systems. The innovative ecosystem – consisting of robot module, gripper, storage station and suitable software – can be integrated quickly and easily, enabling profitable production in a timely manner, even for small quantities – both in terms of the choice of end effector and the choice of robot. MATCH is compatible with all common robots on the market. Thanks to the standardized interface and the option of a manual or automated changeover function, you are equipped for the constantly changing requirements and challenges on the market.

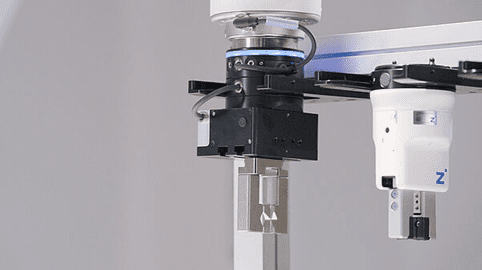

MATCH – robot module

Discover a wide selection of robot modules for robots from the world’s leading manufacturers. Our platform is specially designed for beginners and professional users who are looking for reliable and powerful robot modules for their projects. Browse our range and find the perfect components to realize your innovative ideas.

MATCH – gripper

The wide range of MATCH grippers turns the ecosystem into an automation solution for almost any application. The portfolio is not limited to use in lightweight robotics and human-robot cooperation, but is also suitable for use in industrial and heavy-duty robots. Discover the MATCH end effectors now!

MATCH - Angle flange

- Standardized

Angle flange optimized for the MATCH end-of-arm ecosystem. Rapid change within seconds, suitable for all robots. - Simplest integration

Direct and simple integration of IO-Link grippers from GEP2000, GEP5000, GEH6000IL and GPD5000IL series. - Low interference contour

Compressed air and IO-Link control integrated directly. Optionally available with outlet nozzle and programming tip.

MATCH - Storage station

- Standardized storage station for all MATCH end effectors

- Storage station for automatic tool change

- Optional sensor query of the end effector in the storage station

YOUR BENEFITS

- A single system for lightweight robots, cobots and conventional robots

- Compatibility & flexibility – combining the primary handling technologies (vacuum and mechanical gripping)

- Long service life, even in automated continuous operation

- Innovative digital ecosystem

- Large variety of end effectors

- Manual exchange with easy-click function

- Automated change in the device

- Recommended by ABB, one of the leading manufacturers of robots

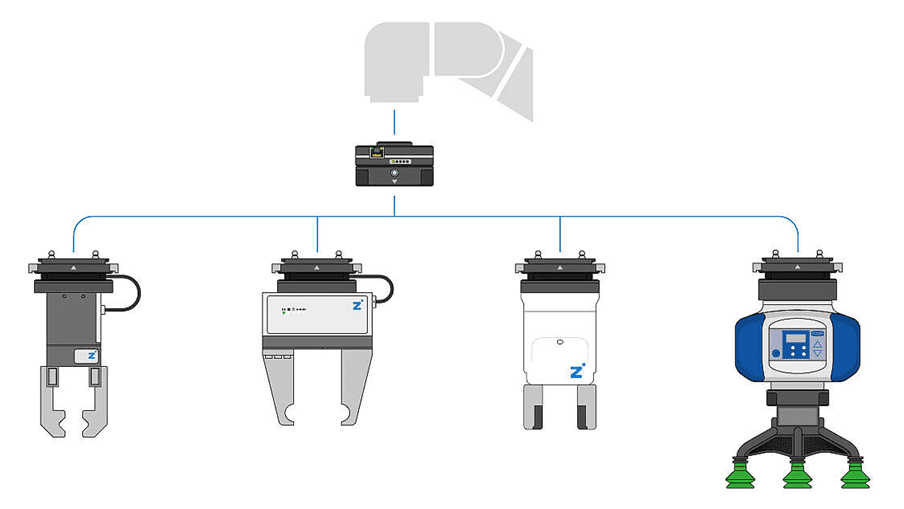

STANDARDIZATION OF THE ROBOT INTERFACE

The MATCH series offers unique standardization potential: The MATCH robot module can be mounted on the most common robot types and acts as a connector for the entire range of MATCH-compatible end effectors. The standardized robot connection flanges offer a high degree of flexibility in the choice of applications. The attached end effectors, whether grippers or suction cups, can be easily exchanged manually or automatically using a click system. Standardized and ready-to-connect solutions guarantee maximum system availability.

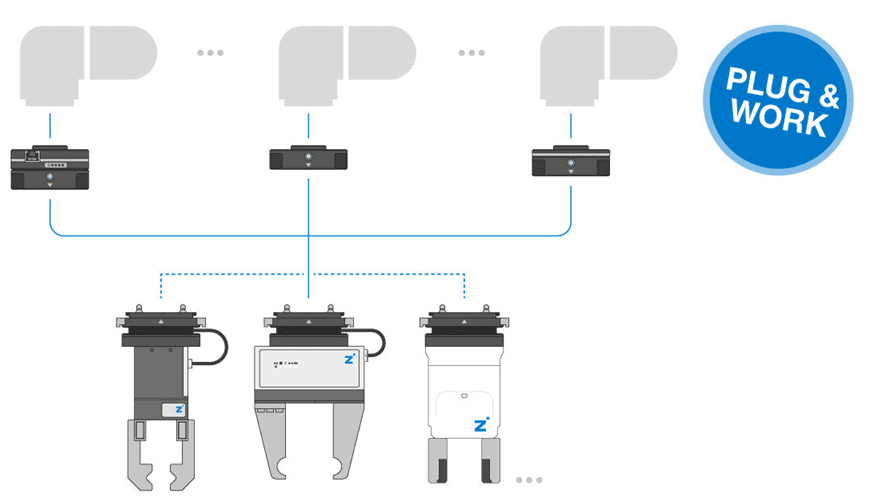

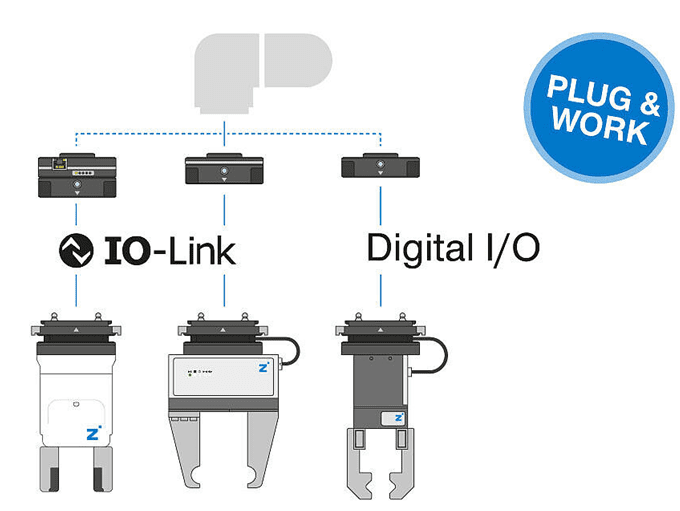

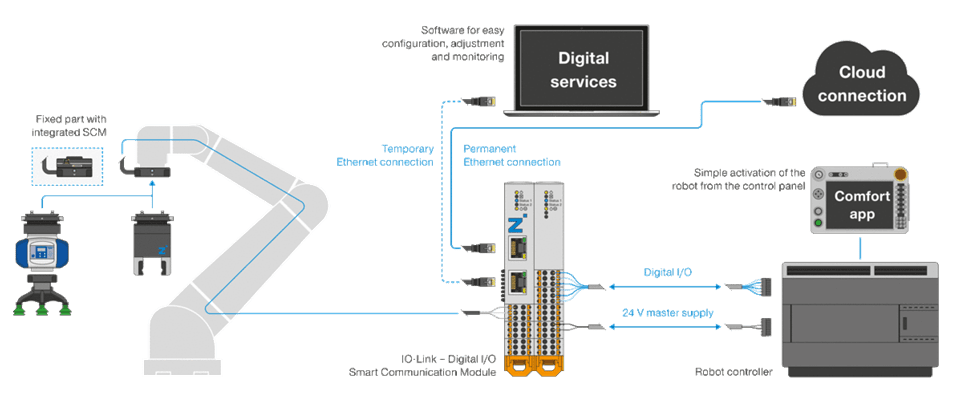

PLUG & WORK – SIMPLIFIED COMMUNICATION INTERFACE

In addition to a uniform mechanical connection between the robot arm and end effector, MATCH also simplifies machine communication. The MATCH robot modules are available in Digital I/O and IO-Link versions or come with their own Smart Communication Module. MATCH provides the necessary communication parameters to integrate robots from different manufacturers with the MATCH system via Plug&Work.

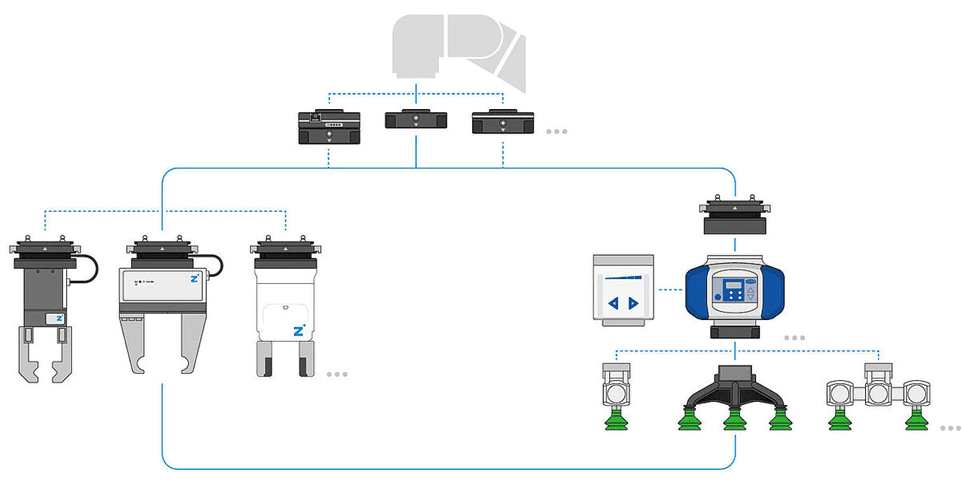

MATCH ECOSYSTEM – LARGE SELECTION OF END EFFECTORS

The MATCH portfolio includes a large selection of Zimmer Group grippers. This is not limited to use in lightweight robotics and human-robot cooperation, but is also suitable for use in industrial and heavy-duty robots. In addition to Zimmer Group grippers, end effectors with vacuum technology from Schmalz are also compatible with the MATCH ecosystem. The MATCH ecosystem consists not only of the physical components, but also includes various software solutions: An app tailored to the respective robot manufacturer enables direct control and monitoring of the functions.

COMPLEX ROBOT APPLICATIONS WITH AUTOMATED SWITCHING

The future of automated production envisages an increase in efficiency through the flexible use of a robot. This means that one and the same robot can perform several different tasks on one workpiece by automatically changing the end effector. In addition, standardization simplifies the process for operators and integrators.

The MATCH product range enables not only an automated change of the end effector but also the use of the same suction cup or gripper by different robot types and systems. The key components here are the MATCH robot modules, which are available for a wide range of robots from the most popular manufacturers.

OPENNESS TO TECHNOLOGY

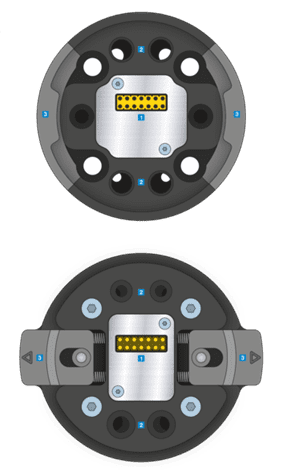

THROUGH STANDARDIZED INTERFACES

The quick-change system has various interfaces. In addition to a compatible mechanical interface and a pneumatic connection, electrical interfaces are also available. This technological openness makes it possible to open up many different robot types with a wide variety of end effectors.

1. Electrical

The quick-change system is hot-pluggable and can be changed under voltage during operation. The integrated pin field transmits both load and signal current.

2. Pneumatics / vacuum

Four internal and two lateral fluid channels supply connected gripper systems with compressed air or vacuum. The generous dimensions enable the operation of powerful pneumatic vacuum generators, for example to handle absorbent cardboard packaging.

3. Mechanical

The high processing quality guarantees a long service life (> 100,000 cycles). An anti-rotation device ensures a clearly defined position of the loose part in relation to the stationary part and a clearly defined orientation of the end effector in the storage station.

SIMPLE INSTALLATION

THANKS TO DIGITAL SERVICES

Installation of MATCH is incredibly easy. The system can be mounted to the robot flange and set up conveniently with just a few manual adjustments. Configuration is intuitive and easy to accomplish thanks to the support of the digital services and the entire ecosystem (SCM module with guideZ, expertZ, monitorZ and Comfort app/cloud connection).

Automated exchange (without external activation)

QUICK-CHANGE FUNCTION

MANUAL AND AUTOMATED

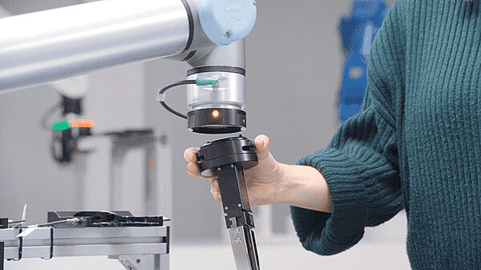

Fast, convenient exchange

The compact quick-change module provides two quick and easy ways to swap a component. In addition to an automated exchange in a storage station, known as the gripper station, exchanging by hand is also possible within seconds. Thanks to the ergonomic click system – integrated on the end effector being changed – it is possible to carry out a manual change with just one hand. At the same time, this prevents the exchange module from falling.

Manual exchange with one-hand function within seconds

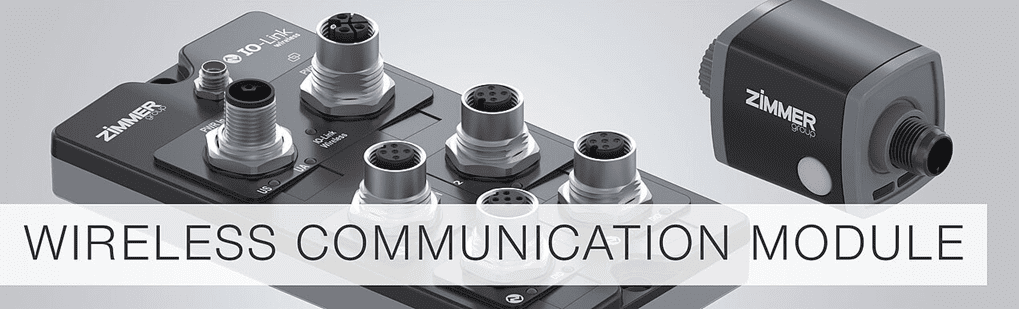

COMMUNICATION

Smart gripper, smart connection

Robot programming made easy: with ready-to-connect communication modules from the Zimmer Group, which you place in the robot control system and, depending on the module, connect to the controller by cable or wirelessly. The Comfort app, which is tailored to the robot manufacturer, allows the gripper to be controlled and operated conveniently and directly via the respective robot control unit – which is easy to set up with all the necessary commands for a smooth automatic mode.

Robot applications can be put into operation with the Zimmer Group’s programming tools – quickly, easily and without in-depth programming knowledge. The Zimmer Group also provides function blocks for download for direct programming in the PLC for all common manufacturers.

With the standardized, wireless IO-Link Wireless communication module, interference-free and secure communication is possible without any cabling. All IO-Link gripper components can be used and are compatible with a wide range of controllers via the standardized interface. Power is supplied as usual via the connecting cable. Energy can be buffered as required, but the information is exchanged directly and wirelessly between the control system and gripper without any delay.

Literature