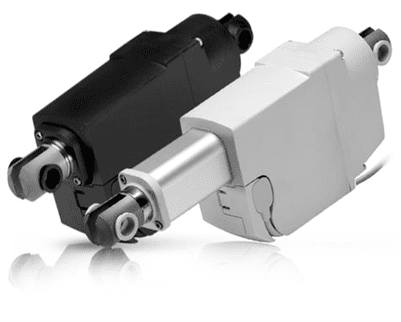

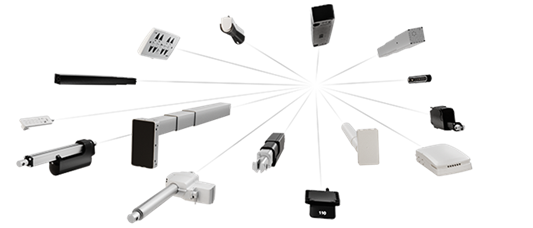

High Quality Linear Actuator Solutions

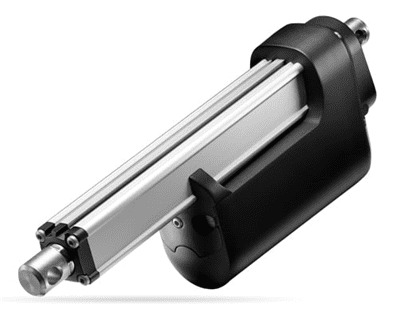

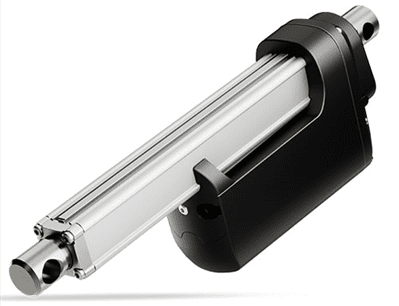

Linear actuators convert rotational motion in motors into linear push-and-pull movements. They are ideal for applications requiring tilting, lifting, pulling, or pushing with force. An electric linear actuator is the preferred solution for simple, safe, and clean movement with precise control. Our actuators come with an IP rating, ensuring protection against dust and water. Besides a linear actuator 12V, we offer variants with 24V, 36V, and 48V. Since creating the first electric linear actuator in 1979, LINAK has led the industry in linear movement technology.

Actuator Solutions for Industrial Automation

Increased efficiency is one of the primary keywords in modern industrial production. Organizations strive to devise new ways to optimize production and reduce energy consumption.

- Changing to low-energy, maintenance-free electric actuators

- Choosing intelligent actuators, tested to withstand harsh conditions

- Having easily installed, customized solutions to improve ergonomics

Save energy and expensive maintenance

Unlike other actuation systems, LINAK solutions do not use any hoses, pumps or compressors. This not only means no risk of leaking oil, it eliminates maintenance, minimizes downtime and significantly prolongs actuator service life. At the same time, the standby energy consumption of LINAK actuators is close to zero, making them the most cost-efficient solution.

Have durable actuator solutions with intelligence

LINAK actuators undergo thorough testing before they are released for sale. They are designed to work in even very harsh conditions and to tolerate washing, without damaging the finer electronics inside. This is important, not only to avoid time-consuming breakdowns, but also to keep employees safe.

Make installation easy and offer improved ergonomics

Electric actuators are easy to install, as they require only a power cord and a data cable connecting them to the industrial machine. LINAK solutions can be customized to fit in almost any industrial machine, and will integrate easily with almost any existing control system. This means significantly better ergonomics.

Literature