Trol Systems Model T6 by Trol Systems

Manufacturer: Trol Systems

Install it:

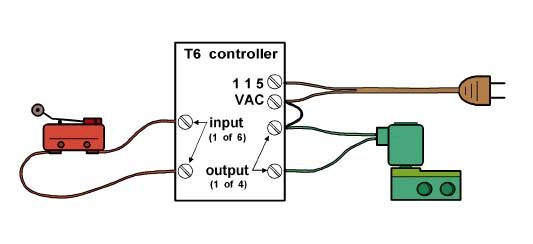

The inputs are connected to switches such as limit, magnetic reed, push button, pressure, etc. The T6 has 6 optically isolated inputs, allowing it to operate in the harshest industrial environments. Inputs are also low in voltage, so they're "shock safe".

The inputs can also connect to electronic sensors such as hall-effect, proximity, optical, etc.

The T6 can even be used without connecting anything to the inputs, such as to perform a timing sequence of the outputs.

Power is connected directly to the controller with no special conditioning required.

The outputs are connected to a valve (air/oil), motor, heating element, solenoid, etc. The T6 has 4 relay type outputs, each rated for 5 amps.

Programming it:

The program determines when loads are energized and when input conditions are checked. The pocket programmer is plugged

into the controller.

You write a program by choosing words from a menu. The program will look similar to notes describing the order in which things happen on your machine. The program is executed in the same order as it is written.

Even a person that didn't write the program can easily understand how it will operate. Unlike PLCs in the past, there's no need to convert your program to electrical symbols, flow charts or mathematical equations.

Up to 575 lines can be programmed in a T6 control. The program is retained without power or batteries for over 10 years. A backup copy of the program is also retained in the pocket programmer for safe keeping.

Use it:

The T6 runs the machine by following your program. The pocket programmer serves as a guide while trouble shooting your machine. You'll always know what the machine is doing... because it tells you in plain English! Use the special "Edit" mode, to make quick changes to your program. Once you get the machine running correctly, just unplug the programmer and reuse it to program additional T6 controllers.

We spent a little more building the T6, but you'll appreciate it! With 1000 volt optical isolated inputs and 2500 volt magnetic power line isolation, the T6 can operate in harsh industrial environments. The bright LED input and output indicators are easy to see, even inside a deep enclosure.

Adjust it:

You can add a Remote Timer* Panel to the front of your machine. It allows the machine operator to adjust timers- while the T6 is running your machine. Adjusting a timer couldn't be easier- just select the name of the timer, then adjust its time up or down. You can set the range of adjustment for each timer and even assign it a custom name. In addition to timers, you can also

program it to display messages.Timer

* A Remote Counter Panel is also available.

Expand it:

The T6 control section has 6 inputs and 4 outputs (a total of 10 I/O). I/O sections can be added as your machine requirements grow. Programming remains easy regardless of how many I/O are added. Each I/O section can be snapped onto a DIN rail or be panel mounted.

Example:

Each cylinder is extended by turning on the output that energizes its valve. The cylinder will retract when the output turns off. Below is a sequential description of how the machine works, followed by the actual T6 program in

red. Example

1. Part is in place, slide is retracted, and the Start button is pressed. Compare inputs 4, 3, 5 - all on

2. Start milling head motor. Output 4 - turn on

3. Clamp the part into position. Output 1 - turn on

4. Lower the milling head. Output 3 - turn on

5. Confirm that head is down. Check input 1 - on

6. Move head to form the slot. Output 2 - turn on

7. Confirm that slot is completed. Check input 2 - on

8. Bring milling head back up. Output 3 - turn off

9. Retract slide to home position. Output 2 - turn off

10. Confirm that slide is back home. Check input 3 - on

11. Stop milling head motor. Output 4 - turn off

12. Allow time for motor to stop. Wait 3.00 seconds

13. Unclamp part for operator to unload. Output 1 - turn off

14. Confirm that the part is removed. Check input 4 - off

15. Ready for next milling cycle. End page

Specifications:

T6 Main Control Unit

Part No. MCU-02-115

Power Requirements:

115vac 50/60Hz. It is also available in12 to 24 vdc @ .3A(30 volts absolute maximum )and 230VAC @ .01A, 50/60Hz w/1000v magnetic isolation

Outputs:

- 4 normally open relay contacts unprotected, no leakage current

- 5Amps @ 230VAC (resistive load), 250 VA (inductive load)

- Response time: 10ms operate / 5ms release

- Rated life: 5 million (mech) / 200,000 @ 3A (resistive load)

Inputs:

- 6 self powered, 12-14 VDC @ 10ma. w/ 1000v optical isolation

- Maximum leakage of input device: 0.5ma

- Response time: all are factory set at 10ms, the user may change any input to between 0 to 255ms using the Setup Menu

Physical:

- Size 2.9" (75mm) x 2.2" (55mm) x 4.3" (110 mm)

- Mounting DIN rail or panel (with two #6 screws)

- Weight 10 oz. (284 grams)

- Temp 0 - 140? F, 90% r. humidity (no condensation)