GX4C SCARA by Epson Robots

Manufacturer: Epson SCARA Robots

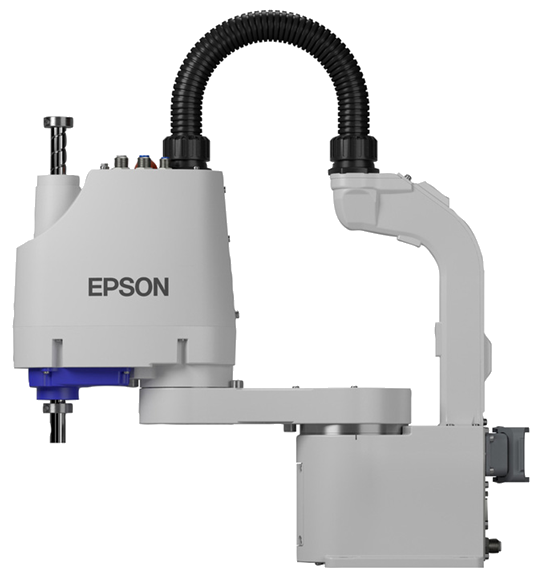

The GX4C SCARA robot delivers next-level performance and flexibility with easy-to-use software and integrated solutions that accelerate workcell development. Engineered to meet the unique needs of automation, it offers multiple arm configurations and SafeSense technology for increased productivity and worker protection while potentially minimizing machine footprint.

Engineered to meet your unique automation needs, the GX4C offers multiple arm configurations and a 250 mm, 300 mm or 350 mm reach to accomplish the most demanding tasks with ultra high precision. Its innovative, compact design easily integrates into cleanroom or ESD environments and handles payloads of up to 4 kg from a conveniently small form factor. Combined with SafeSense™ technology, which can potentially remove the need for physical safety barriers with a proper risk assessment, users can reduce the footprint and overall cost of their robot automation system.

Designed for ease of use, Epson RC+® software works seamlessly with the GX4C to create powerful automation solutions and offers integrated options to simplify the most complex applications. Fully integrated solutions—including vision guidance, part feeding, force guidance, conveyor tracking and fieldbus—accelerate the development of workcell applications, saving valuable time and money. The Epson RC+ Solutions Platform allows for seamless expansion of third-party solutions, benefiting both developers and end users.

Product Highlights

- Ultra high performance and flexibility

- Fast cycle times with patented GYROPLUS technology

- Easy-to-use, powerful Epson RC+ software

- Designed for reliability

- Accelerate application development with optional integrated solutions

What's in the box:

- GX4C robot and RC800A controller

- E-Stop unit with cable and connector

- cable with flying leads for controller

- E-stop/Safety connection

- connector set (I/O, hand I/O and safety circuit connectors)

- Ultra high performance and flexibility — high throughput with max-rated payloads and multiple arm configurations to accomplish the most demanding assembly needs

- Fast cycle times — high acceleration, smooth motion and fast settling times help maximize throughput with proprietary GYROPLUS vibration reduction system, plus no ringing or overshoot1

- Ultimate ease of use — intuitive and feature-packed Epson RC+ development software helps create powerful solutions with a simple user interface, integrated debugger and advanced 3D simulator

- Designed for reliability — innovative, compact design handles max-rated workloads at fast speeds and high precision within a small footprint

- Low total cost of ownership — includes features that help reduce support and installation costs: batteryless encoders, a built-in Ethernet cable, Epson RC+ software and a rich suite of safety features

- Accelerate the development of workcell applications — fully integrated, optional solutions include vision guidance, parts feeding, force guidance, conveyor tracking and fieldbus; Epson RC+ Solutions Platform allows for seamless expansion of third-party solutions, benefiting developers and end users

- Increase user interaction without sacrificing productivity — SafeSense technology’s standard and advanced safety features, with a proper risk assessment, help allow for increased productivity and worker protection while potentially minimizing machine footprint due to the reduction of physical barriers

- Minimize the workcell space requirement with an optimized robot footprint — multiple mount and cable exit options; 250 mm, 300 mm or 350 mm reach available; unique curved arm (350 mm) option maximizes work envelope

- Built for demanding environments — Standard, Cleanroom (ISO 3)2 and ESD, and standalone ESD models available

Literature